Industrial Equipment Solutions

HFF SCREENS

Food Grade

Food Grade Screen (SUGAR, SODA, SALT, SCALPING ETC)

We design and install custom made Stainless Steel Screens for Fine Screening of Food Grade bulk material to fit your facility's unique needs. Our team of experts will work with you to create a solution that maximizes efficiency and productivity.

DAP/NPK/NP/Urea/Potash/Rock Phosphate Screening

Our HFF Screening Technology is most suitable for Hygroscopic products screening

Quartz/ Quartzite/ Silica

Special minerals for manufacturing Engineered Products need high quality of separation . Vibfem HFF High Frequency Classifier Screens is most suitable for special minerals screening.

Limestone/ Feldspar/ Graphite

We supply suitable screening technology for special minerals that need fine separation at very high efficiency.

Turnkey Projects- EPC Contracts

We undertake complete EPC contracts for various grinding and screening requirementand also work on Design-Build-Operate-Maintain mode.

Video

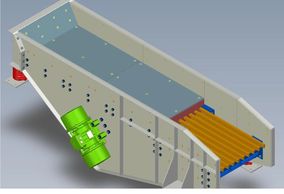

VIBFEM HFF Screen.

Most advanced in features, working at 6000rpm, Special Controller for frequency and amplitude adjustments, proprietary automatic media cleaning technology, variable deck inclination, touch screen operations.

VIBFEM You tube Channel for all Videos

https://www.youtube.com/channel/UCxaxKzI4X9ZlzFFiNSkqpRg

About Us

Experience

VIBFEM has in excess of 25 years of experience in mining, aggregate, aerospace, railway and automotive industries. Experience on different projects in Europe, North and South America, Africa, Australia and Asia.

VIBFEM:

- Engineering, Design, Procurement, Construction of Various Medium and Large Scale Engineering Projects

- Turnkey Greenfield and Brownfield Solutions

- Specialised Engineering Solutions for crushing, grinding, Screening, waste to value, recycling processes

- Screening and Sorting Equipment for Fertilizers Like DAP/NPK/Urea/Potash Etc, High Frequency Screening in Special Minerals like Quartz, Silica, Limestone, Quartzite, Graphite, Etc

- Cooperates with several companies offering specialised engineering services and creating JVs for bigger project

- Specialises in mining and aggregate plant efficiency improvements and de-bottlenecking

- Offers extensive experience in vibrating screens and feeders design, installation and commissioning

- Provides design, fabrication and installation of replacement screens to suit current installation layout

- Provides 3D modeling and drafting

- Provides chute design using DEM

- Special screen for sand plant Variable high frequency screen, m-sand high frequency screen

- Custom made screening machines

Customised Screen for Various Applications

We provide various types of screens for your application , let us know.

APPLICATIONS

- M sand High Frequency Screen

- Construction sand

- Plaster sand

- Fertilizer

- Soda Ash

- Sugar

- Food

- Pigments

- Pharma

- Waste handling

- Slag handling

- Limestone

- Gypsum

- Quartz sand

- Frac Sand

- Cement

- Heavy minerals

- Rare earth

- Recycling

- Auto Shredder Residue (ASR)

- Municipal Solid Waste (MSW)

- Construction & Demolition (C&D)

- E-Scrap

- Crushed Glass / Cullets

- Recycled Concrete

- Food Scraps & Organic Materials

MORE APPLICATIONS:

- Plastic Chips screening machine

- Waste Slag (Steelworks)

- Compost

- Wood Products

- Remove Abrasive Fines from Boiler Fuel

- Wood Chips, Sawdust, & Wood Flour

- Fine Pulp

- Mineral Processing / Aggregate

- Sand

- Crushed Stone

- Iron / Copper Ore

- Recycled Asphalt (RAP)

- Coal, Coke & Iron Ore Fines

- Limestone & Dolomite

- Excavated Soils

- Basalts

- Gypsum

- Bauxite

- Other

- Bio-Solids

- De-Dusting

- Incinerator Ash

- Shredded Materials

- Animal Fodder

- Chemicals

- Dredged Materials and more...

Special Sand Plant

We offer M sand High Frequency Screen (VIBFEM HFF Screen) for manufacturing construction sand as per Zone II and plaster sand as per IS 1542.

Very fine silt -150 micron is removed from manufactured sand by our Variable frequency Vibrating Screen (VIBFEM HFF Screen).

VIBFEM HFF screening machine removes silt easily from crushed sand , lowest power , highest efficiency, works clog free due to automatic dual cleaning mechanism where clogged material is loosened with very high G Force generation followed by resonance knocking. Works at normal moisture used during crushing. No recirculation of product due to very high efficiency.

VIBFEM HFF Screen can be fitted in any existing crushing plant to process sand and remove silt.

It is Australian technology, Made in India.

We focus on efficiency and quality of sand.

We give complete solution for sand manufacturing with Sand mill, Variable High frequency screen with packaging machines.

Our aim is to give customer best of class offer in manufacturing sand by environmental friendly method, low cost of operation and low cost of acquisition by locally manufacturing in India.

The quality of sand manufactured by our plant is best in the market and will fetch our customer premium price due to high grading quality.

Products

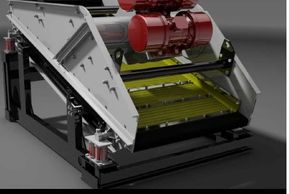

Variable HFF screen

Variable HFF screen

Variable HFF screen

APPLICATIONS

- M sand High Frequency Screen

- Construction sand

- Plaster sand

- Msand

- Fertilizer

- Soda Ash

- Sugar

- Food

- Pigments

- Pharma

- Waste handling

- Slag handling

- Limestone

- Gypsum

- Quartz

- Frac Sand

- Cement

- Dolomite

- Feldspar

- Silica

- Quartzite

- Potash/ Kali

- Graphite

- Heavy minerals

- Rare earth and more...

Custom made sizes and number of decks as per application need.

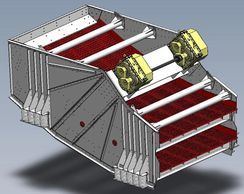

HYBRID SCREEN

Variable HFF screen

Variable HFF screen

APPLICATIONS

- Tough Screening application where material is sticky, do not travel easily, fibrous, odd shaped (broken glass cutlets, fine dust, hygroscopic, wastes, etc)

- This technology has both - the linear motion body movement , and the high frequency direct excitation mesh vibration

- One of its kind unique design

- Single deck or multi deck

- High efficiency screening

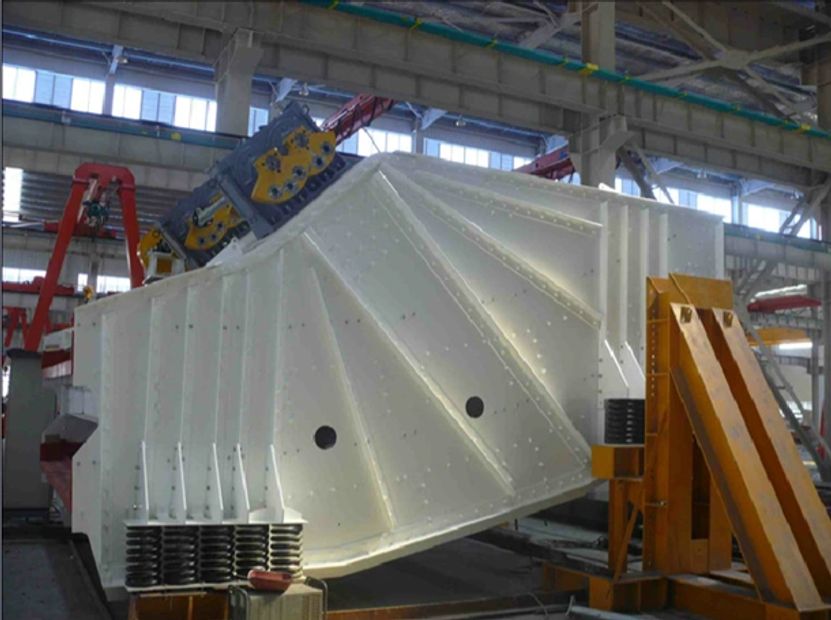

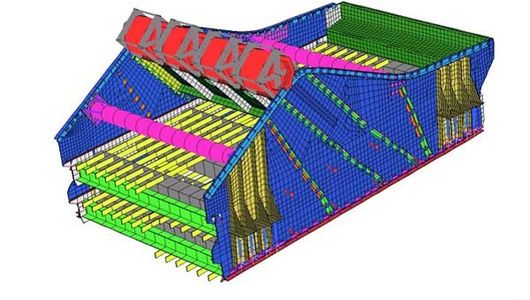

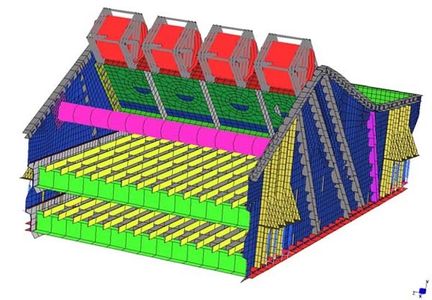

Flip Flow Screen

Variable HFF screen

Flip Flow Screen

APPLICATIONS

- Recycling

- Auto Shredder Residue (ASR)

- Municipal Solid Waste (MSW)

- Construction & Demolition (C&D)

- E-Scrap

- Crushed Glass / Cullets

- Recycled Concrete

- Food Scraps & Organic Materials

- Plastic Chips

- Waste Slag (Steelworks)

- Compost

- Wood Products

- Remove Abrasive Fines from Boiler Fuel

- Wood Chips, Sawdust, & Wood Flour

- Fine Pulp

- Mineral Processing / Aggregate

- Sand

- Crushed Stone

- Iron / Copper Ore

- Recycled Asphalt (RAP)

- Coal, Coke & Iron Ore Fines

- Limestone & Dolomite

- Excavated Soils

- Basalts

- Gypsum

- Bauxite

- Other

- Bio-Solids

- De-Dusting

- Incinerator Ash

- Shredded Materials

- Animal Fodder

- Chemicals

- Dredged Materials and more...

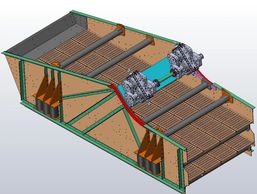

Resonance Screen

Dewatering screen

Flip Flow Screen

- Wet and dry screening of heavy minerals

- Wet and dry screening of Coal

- Manganese

- Iron Ore

- Phosphates

- Gravels

- For fine and medium separation sizes up to 70 mm

- Building materials, industrial minerals

- Recycling industry

- Longest screening area and lowest installation height of any screen

- Multiple separation sizes per deck is possible

- High screening efficiency in horizontal screening

- Low Power consumption

- Negligible vibration to supporting structure

Banana Screen

Dewatering screen

Dewatering screen

Custom made banana screen for your application contact us for more

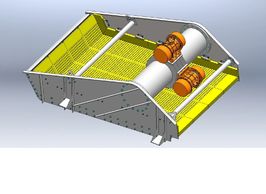

Dewatering screen

Dewatering screen

Dewatering screen

Custom made dewatering screen, contact us for more

Horizontal screen

Horizontal screen

Horizontal screen

Horizontal screen for higher efficiency screening with high quality product, contact us for more

Grizzly Feeder

Horizontal screen

Horizontal screen

Grizzly feeder for coal and other minerals , contact us for more..

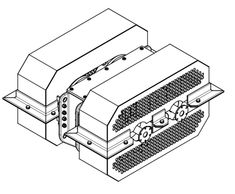

Exciters

Horizontal screen

Exciters

VIBFEM Patented Exciters for your Vibrating Screens, fits any footprint.

New design with all bearings sump-lubricated in all positions, eliminated dry runs resulted from unreliable splash lubrication - no gears so lower noise level.

Self synchronizing, no metal debris from soft gears, lower temperature because of improved lubrications and no gears generated heat.

More reliable operation and longer bearings life. Reduced weight and cost.

Brochures Downloads

Dual Frequency Screen (pdf)

DownloadFlip-Flow_Screens (pdf)

DownloadResonance-Screens (pdf)

DownloadVibrating Screens-Banana (pdf)

DownloadVibrating Screen-Horizontal (pdf)

DownloadVibrating Screens-Dewatering (pdf)

DownloadVibrating screen-Circular Motion (pdf)

DownloadGRIZZLY FEEDERS – GF SERIES (pdf)

DownloadGRIZZLY FEEDERS – PG SERIES (pdf)

DownloadGearless Exciters (pdf)

DownloadVIBFEM Mining Screen Gallery

ATTRACTIVE CUSTOMER OFFER

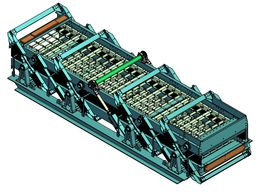

SUGAR GRADERS

High Efficiency Sugar Graders. Available in multiple decks, direct excitation, high frequency excitation, bottom decks with additional direct excitation options. Food grade MoC. CE and Atex Certification.

HIGH FREQUENCY DIRECT EXCITATION SUGAR AND FOOD GRADERS

Vibfem Sugar Graders are advanced in features, each deck can be directly excited at high frequency. Every grader comes with Automatic Media Cleaning Technology using special controllers. Equipment can be remotely monitored. Variable frequency and variable amplitude of operations based on requirement.

QUARTZ PROCESSING PLANT

Turnkey Setup of special Quartz Plant. CONTACT US FOR MORE INFORMATION.

EPC Turnkey Projects, Design-Build-Operate by VIBFEM

Take our expertise in Engineering Projects Consultancy for your production plant and get turnkey deal for plant to run it 24 X 7 trouble free for more detail write to sales@vibfem.com

MATERIAL HANDLING EQUIPMENT, MATERIAL PROCESSING MACHINES, D

BUCKET ELEVATORS- SS, Atex, CE, Food grade

MATRIAL HANDLING, CONVEYORS, ELEVATORS, DELUMPERS, SILOS, FE

HANDLING EQUIPMENT

Bucket Elevators, SS material, food grade, fire safety, Atex, CE certified. Food grade belt. SS and MS lumps breaker for Sugar, Urea, etc. Silos, hoppers, feeder, scalping. Automation, SCADA, DCS, IoT.

Message from dr ziggy gregory

VIBFEM has in excess of 25 years of experience in mining, aggregate, aerospace, railway and automotive industries. Experience on different projects in Middle East, Europe, North and South America, Africa, Australia and Asia.

We at VIBFEM are committed to customer productivity, profitability by providing best suited equipment with total solution befitting process and quality requirement.

Each of our Products like Circular Motion screen , Variable High frequency screen, Flip Flow screen, Conveyors, feeders, Scalpers, Material Handling Equipment, Crushing/Grinding/Sorting/Screening/Packing plant is best in class in terms of performance, quality, energy requirement.

We believe ourselves to be your solution provider for classifying and handling. Each equipment is custom designed suiting your need.

Our engineers are working round the clock to meet your product, process and quality requirement backed with a strong service team.

VIBFEM is continuously expanding its presence across the globe through various turnkey and EPC projects.

VIBFEM India is doing excellent job by providing world class, environment friendly, cost effective, durable, best in class Screening Solution, saving on energy and natural resources like water.

We invite you to experience VIBFEM unmatched product and service.

Dr Ziggy Gregory

PhD Mechanical Engineering

NEWS

Dr Ziggy Gregory presenting at IQA 2019 Australia - VIBFEM Screening Technology

see the full presentation in download section above VIBFEM PRESENTATION

Contact Us

Dealership enquiry solicited write on sales@vibfem.com

VIBFEM Equipment Pvt Ltd

Works Address

Hours

Mon | 09:00 am – 05:00 pm | |

Tue | 09:00 am – 05:00 pm | |

Wed | 09:00 am – 05:00 pm | |

Thu | 09:00 am – 05:00 pm | |

Fri | 09:00 am – 05:00 pm | |

Sat | Closed | |

Sun | Closed |